Skip to key material Will not pass up tomorrow's biopharma industry information Enable BioPharma Dive's cost-free e-newsletter keep you knowledgeable, straight out of your inbox.

Specialized understanding: Lyophilization cycles are not “one-sizing-suits-all,” and considerable cycle growth is needed for each merchandise. This will likely contain a number of scientific studies to grasp the freezing and drying habits of formulation parts as well as investigations into how formulation strengths or containers impact the freeze-drying process.

We hope to guidance the scientific community to spare time, effort and funds, whilst drawing interest to your wide selection of opportunities provided by freeze drying in pre-clinical or primary exploration.

Substantial cash financial commitment: Massive-scale lyophilization for sterile products needs multi-million dollar investments into products and facility servicing (find out more about sterile manufacturing and aseptic processing below). As a result, equally little and enormous pharmaceutical providers will usually transfer their lyophilization processes to deal development and manufacturing companies (CDMOs) for scientific and professional producing.

Take into consideration Individuals lightweight, nonetheless taste-packed freeze-dried berries within your cereal or the instant coffee that wakes you up in the morning.

Comparison of scatter in frozen and lyophilized, pulverized samples from fibrotic kidneys. a Representative Masson's trichrome-stained sections of diabetic rat kidneys. Arrows display examples of focal fibrosis.

"Several biotech companies are fairly modest in size and might have minimal means. They could often not have in-home formulation progress capabilities or tools and seek to outsource to your CDMO that has the capability, expertise and capabilities to support," suggests Glimpse.

Secondary drying is done if the residual moisture is low plenty of to make sure that the product will here continue being stable right until the expiry day.

We’d love website to show you more about Millrock Technologies. Allow us to know the way we might help/what inquiries you've.

Lyophilization is a value-efficient method for Organic specimen preservation but comprehensive tissue-distinct reference protocols are still lacking. Additionally, knowledge are limited within the extended-term balance of proteins and nucleic acids in lyophilized samples.

As an inaugural member with the Process Enhancement staff, Matt now manages highly competent researchers in exactly the same team, leveraging his process awareness and specialized prowess to tell experts and clientele alike, from smaller scale preclinical assessments to late-phase characterization and aseptic fill-complete. Matt gained his B.S. in Chemical Engineering from the College of Massachusetts.

An optimal formulation makes certain successful sublimation and lessens the chance of product collapse or degradation during the process. In this regard, the formulation phase is vital to ensuring that the final lyophilized solution is stable, successful, and safe for use.

Ad cookies are utilized to deliver people with applicable adverts and advertising strategies. These cookies keep track of guests throughout websites and collect data to offer tailored ads. Other individuals Others

Condenser: The guts and soul from the freeze dryer. Its Main functionality is usually to entice the h2o or solvents as they sublimate off the product or service. Positioned adjacent to or under the leading chamber, the condenser cools these vapors, turning them back again into a reliable variety, which then accumulates as ice about the condenser floor.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Neve Campbell Then & Now!

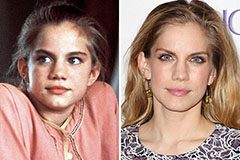

Neve Campbell Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now!